REDUCING WASTE DENGAN MENGGUNAKAN PENDEKATAN LEAN MANUFACTURING

Akhmad Jakfar, Wahyu Eko Setiawan, Ilyas Masudin

Abstract

PT. XYZ is one of some cigarette companies in Indonesia. In producing cigarette, the firm requires

DOI:

http://dx.doi.org/10.12928/si.v13i1.1837

Refbacks

There are currently no refbacks.

This work is licensed under a

Creative Commons Attribution-ShareAlike 4.0 International License .

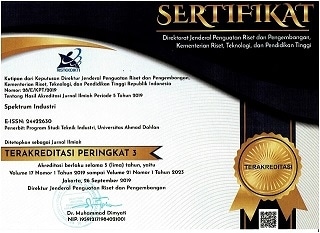

Jurnal SPEKTRUM INDUSTRI Indexed by:

View Spektrum Industri Stats

<div class="statcounter"><a title="Web Analytics Made Easy - StatCounter" href="https://statcounter.com/" target="_blank"><img class="statcounter" src="https://c.statcounter.com/12044963/0/0f596a27/0/" alt="Web Analytics Made Easy - StatCounter"></a></div>

Ciptaan disebarluaskan di bawah Lisensi Creative Commons Atribusi-BerbagiSerupa 4.0 Internasional

.png)