PENJADWALAN FLOWSHOP DENGAN MENGGUNAKAN SIMULATED ANNEALING

Muhammad Firdaus, Ilyas Masudin, Dana Marsetya Utama

Abstract

This article apply a machine scheduling technique, named Simulate Annealing (SA) to schedule

DOI:

http://dx.doi.org/10.12928/si.v13i1.1836

Refbacks

There are currently no refbacks.

This work is licensed under a

Creative Commons Attribution-ShareAlike 4.0 International License .

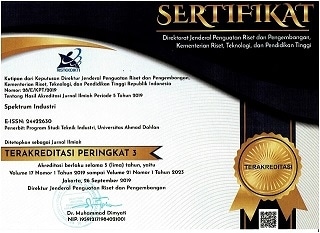

Jurnal SPEKTRUM INDUSTRI Indexed by:

View Spektrum Industri Stats

<div class="statcounter"><a title="Web Analytics Made Easy - StatCounter" href="https://statcounter.com/" target="_blank"><img class="statcounter" src="https://c.statcounter.com/12044963/0/0f596a27/0/" alt="Web Analytics Made Easy - StatCounter"></a></div>

Ciptaan disebarluaskan di bawah Lisensi Creative Commons Atribusi-BerbagiSerupa 4.0 Internasional

.png)