IMPROVEMENT OF WORK METHOD TO REDUCE REPETITIVE WORK IN PT. TRIJAYA PLASTIK UTAMA WITH OCRA METHOD

Abstract

Keywords

Full Text:

PDFReferences

Anwar, S., Putri, A. (2017). Application of the Occupational Repetitive Actions (OCRA) Index to Assess Ergonomics Risks of Corn Seed Production Workers. Proceeding Seminar Nasional Teknik Industri Universitas Gadjah Mada, Yogyakarta, pages ER 112-ER 119

Chiasson, M., Imbean, D., Aubry, K., and Delisle, A. (2012). Comparing the Result of Eight Methods Used to Evaluate Risk Factors Associated with Musculoskeletal Disorders. International Journal of Industrial Ergonomics, Vol. 42, pages 478-488

Colantoni, A., Marucci, A., Monarca, D., Pagniello, B., Cecchini, M., and Bedini, R. (2012). The Risk of Musculoskeletal Disorders Due to Repetitive Movement of upper Limbs for Workers Employed to Vegetable Grafting. Journal of food, Agricultural & Environment, Vol. 10 (3&4), pages 14-18

Febrianti, A., Indrawan, R., dan Desrianty, A. (2017). Usulan dan Rancangan Simulasi Perbaikan Stasiun Kerja JSW 2000 Menggunakan Metode Occupational Repetitive Action (OCRA) Index. Proceedings Seminar Nasional VII Manajemen dan Rekayasa Kualitas,Bandung, pages C5-1 – C5-9.

Franseda., Effendi, F., Widyahening, I.S., Satrya, C., and Roestam, A. (2014). Prevalensi Upper Extremities Work Related Musculoskeletal Disorders (UE-WRMSDs) dan Hubungannya Dengan Faktor Biomekanika Kerja Berdasarkan Pengukuran Occupational Repetitive Action (OCRA). J. Indon Med Assoc, Vol. 64 No. 10, pages 463-468

Habibi, E., Zare, M., Haghi, A., Habibi, P., and Hassanzadeh, A. (2012). Assessment of Physical Risk Factors Among Artisans Using Occupational Repetitive Actions and Nordic Questionnaire. International Journal of Environmental Health Engineering, Vol. 1 Issue 8, pages 1-6

Joseph, C., Imbeau, D., and Nastasia, I. (2011). OCRA: Measurement Consistency Among Observational Job Analysis Methods During an Intervention Study. International Journal of Occupational Safety and Ergonomics (JOSE), Vol. 17 No. 2, pages 139-146

Madia, H., Elena-Ana, P., Florina, G., and Delia, C. (2006). The OCRA Score and the Risk Evaluation of Musculoskeletal Disorders in a Group of Textile Industry Workers, Cercetari Experimentale & Medico-Chirurgicale, Annul XIII, Nr. 3-4, pages 212-215

Ma’ruf, F., Adiyanto, O., & Triesnaningrum, H. F. (2020). Analisa Biomekanika Pada Aktivitas Penyetrikaan Studi Kasus Nafiri Laundry Yogyakarta. Jurnal Ergonomi Dan K3, 5(1), 11–19.

Motamedzade, M., Mohammadiyan, M., and Faradmal, J. (2018). Comparing of Four Ergonomics Risk Assessment Methods of HAL-TLV, Strain Index, OCRA Checklist and ART for Repetitive Work Tasks. Iranian Journal of Health, Safety & Environment, Vol. 6 No. 3, pages 1303-1309

Nadri, H., Fasih, F., Nadri, F., and Nadri, A. (2013). Comparison of Ergonomics Risk Assessment Outputs from Rapid Entire Body Assessment in An Anodizing Industry of Tehran, Iran. JOHE, Vol. 2, pages 195-202

Najarkola, S.A.M. (2006). Assessment of Risk Factors of Upper Extremity Musculoskeletal Disorders (UEMSDs) by OCRA Method in Repetitive Tasks. Iranian Journal of Public Health, Vol. 35 No. 1, pages 68-74

Occhipinti, E., and Colombini, D. (2004). The Occupational Repetitive Action (OCRA) Methods: OCRA Index and OCRA Checklist. In A Stanton, N., Hedge, A., Brookhuis, K., Salas, E., Hendrick, H (Eds), Handbook of Human Factors and Ergonomics Methods (pp. 15-1 – 15-14), Boca Raton, CRC Press

Pembayung, D., Suhardi, B., Astuti, R.D. (2018). Penilaian Postur Kerja Menggunakan Metode Quick Exposure Checklist (QEC) di IKM Tahu Sari Murni. Performa, Vol. 17 No. 1, pages 24-30

Reis, D.C.D., Tirloni, A.S., Ramos, E., and Moro, A.R.P. (2017). Assessment of Risk Factors of Upper-limb Musculoskeletal Disorders in a Chicken Slaughterhouse. Proceedings of The 2nd Asian Conference on Ergonomics and Design, pages 458-461

Roman-Liu, D., Groborz, A., and Tokarski, T. (2013). Comparison of Risk Assessment Procedures used in OCRA and ULRA Methods. Ergonomics, Vol. 56 No. 10, pages 1584-1598

Ruddy, F., Eduardo, M., and Edoardo, S. (2012). Application of the OCRA Method in the Sugar Cane Harvest and Its Repercussion on the Workers’ Health. Preliminary Study. Work, Vol. 41, pages 3981-3983

Sari, F.P., Suhardi, B., Astuti, R.D. (2017). Penilaian Postur Kerja di Area Konstruksi CV. Valasindo dengan Metode Quick Exposure Check. Performa, Vol. 16 No. 2, pages 107-113

Sharma, P., Singh, M.P. (2016). Risk & Postural Assessment Using Ergonomics Design OCRA Method in Production of Bearing Race. International Journal of Mechanical And Production Engineering, Vol. 4 Issue 6, pages 80-90

Susihono, W., Prasetyo, W. (2012). Perbaikan Postur Kerja untuk Mengurangi Keluhan Muskuloskeletal dengan Pendekatan Metode OWAS (Studi Kasus di UD. Rizki Ragil Jaya Cilegon). Spektrum Industri, Vol. 10 No. 1, pages 69-81

The International Organization Standardization (ISO). (2007). Ergonomics–Manual Handling – Part 3: Handling of Low Loads at High Frequency. Geneve: ISO

DOI: http://dx.doi.org/10.12928/si.v18i2.14957

Refbacks

- There are currently no refbacks.

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

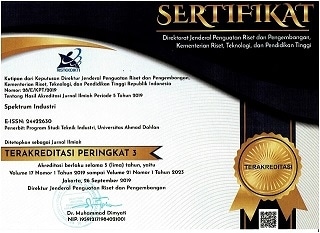

Jurnal SPEKTRUM INDUSTRI Indexed by:

Ciptaan disebarluaskan di bawah Lisensi Creative Commons Atribusi-BerbagiSerupa 4.0 Internasional

.png)